Mite Control While Honey is on the Hive: Part 4

Mite Control While Honey is on the Hive

Part 4

First Published in ABJ February 2021

Randy Oliver

ScientificBeekeeping.com

In the three previous articles in this series, I showed the results of my field trial of summer mite treatments. Now let’s go a little further with extended-release oxalic acid (OAE).

A Note on Terminology

Following the commonly-used acronyms OAV for vaporization, and OAD for dribble application, I’m shortening the acronym that I’ll use for extended-release oxalic acid to “OAE.” OA will refer to oxalic acid dihydrate, and “gly” for glycerin.

Findings by Others

Studies by Geoff Williams and Jennifer Berry in Georgia suggested that OAE on shop towels did not exhibit as good, or as consistent an efficacy as I repeatedly obtain in California. I was curious as to why that was, and have tried to line up additional collaborators in areas with high humidity, to see whether humidity was the explanatory factor. Unfortunately, a planned collaborator at Florida A&M University, Dr. Lee Bushong, was forced to forego a field trial this year due to the pandemic.

However, one ambitious teenager, Soren Roberts, was able to run a small trial in humid Virginia. We report his findings in a separate article in this journal.

In a recent study from Ontario, Canada, Sabahi [[1]] obtained nearly 80% efficacy in reduction of the total mite population in the hives (as opposed to the reduction in the infestation rate that I measure) after only 4 weeks of treatment, using a low-saturation formula of OA/gly on shop towels, placed on the top bars of single-deep colonies. Those good results were despite the fact that such lack of exposure of the bees to the upper surface of the towel allows for only minimal contact of the bees to the OA/gly towels. Sabahi’s findings also suggest that we need to further investigate extended-release of thymol in glycerin.

The Effect of Treatment Upon Colony Condition

As far as I can tell, every treatment for varroa has its cost. Some irritate the adult bees, some kill eggs, larvae, or queens, some suppress egglaying, some adversely effect bee immunity or behavior. Oxalic acid is no exception [[2]]. Surprisingly, there are few reports of adverse effects from OAE. However, Sabahi noticed slightly elevated adult bee mortality in small colonies continually treated with OA/gly.

So the question for any mite treatment is always, does the benefit to the colony from mite reduction outweigh the cost of treatment (as far as adverse effects)?

Practical application: Beekeepers are sooo danged predictable — one of the first questions that I hear about OAE is “Will we be able to keep it on our hives year-round?” I seriously doubt that that would be a good idea, as I can’t imagine that there are no adverse effects even from low-level continual exposure to OA.

In a previous trial with 18 g OA in glycerin on shop towels, I did not detect any adverse effect [[3]]. But in other experimentation, I’ve observed adverse effects upon the bees and brood when I applied 18 g of 1:2 w:w OA:gly on either two half shop towels or an equal surface area of chipboard (Figures 1 & 2).

Fig. 1 Only when I’ve applied matrices with a high ratio of glycerin to OA have I observed agitation and bearding of the bees. This photo was taken on a spring day the day after application of towels prepared with eight different ratios of OA to glycerin. The hives which received the other seven ratios did not exhibit bearding.

Fig. 2 When I opened the hive, it was easy to see that the bees were agitated, spaced apart, and avoiding contact with the saturated towels. With the other test formulations, there was no apparent agitation, and bees were walking over the towels.

Practical application: The Argentinian Aluen CAP formulation [[4]] uses the ratio of 1 g OA to 2 mL glycerin. One advantage of this ratio is that the OA can be dissolved at room temperature, and it doesn’t crystallize on the strips. A disadvantage, besides the possibility of dispersing the OA onto the bees too rapidly (causing adult agitation and brood kill), is that this uncrystallized acid solution sticks to your hands (and anything else that they touch) during application. This is why I prefer the 1:1 (by weight) ratio.

In previous trials, I haven’t applied more than 18 g of OA to a hive, so it was with some trepidation that I applied 50 g of OA in the two-sponge treatment in this trial. As far as adverse effects upon the brood, I’ll let you decide for yourself (Figure 3).

Fig. 3 I was concerned that the two-sponge OA/gly treatment might disperse too much OA and cause adverse effects upon the brood. This did not appear to be the case, as evidenced by the brood pattern in this typical double-sponge (50 g) treated hive at the end of the trial. Keep in mind that many of these colonies had very high mite counts and lousy brood patterns at the start of the trial. It was impressive to see how well they could recover with an efficacious treatment.

Practical application: This trial was not designed to measure adverse effects or honey production, but our informal field observations indicated that colonies in which the mite counts were quickly reduced to low levels performed better, as far as colony growth and honey production. So for quick mite knockdown, Formic Pro might be the best choice.

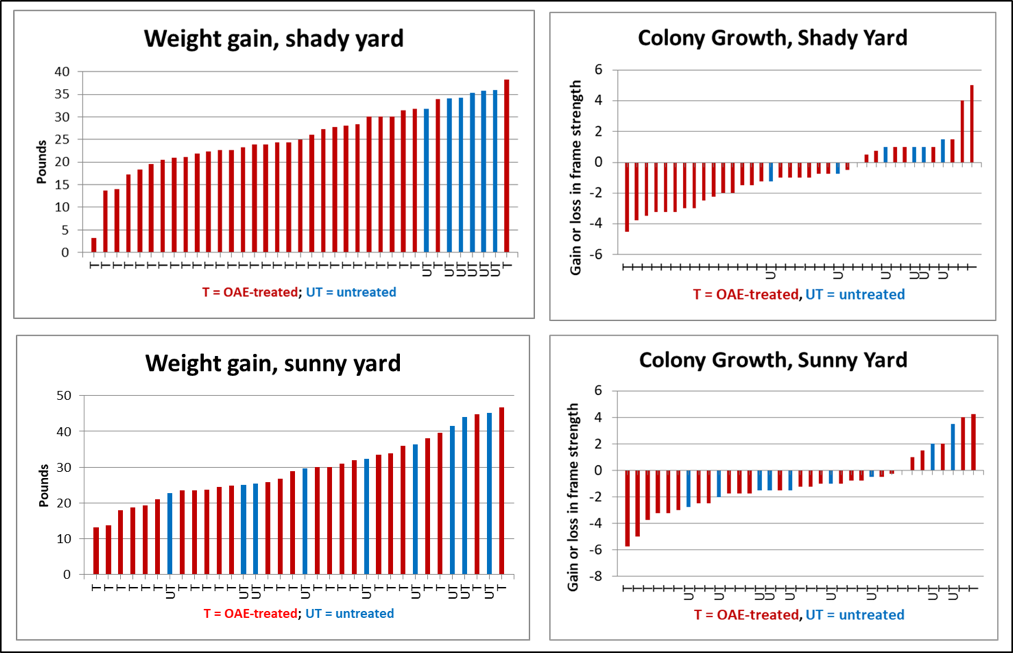

On the other hand, I performed another field trial this season in which I did measure colony strength and honey production in two different yards. All the hives received OAE treatment, other than a scattering of potentially mite-resistant colonies that received no mite treatments. Something that caught my attention was that the untreated (naturally-resistant) colonies seemed to be performing very well relative to at least some of the OAE-treated hives. So I worked up the data (Figure 4).

Fig. 4 The Shady Yard data (upper left) sure made it look as though OAE treatment (red columns) may have had a negative effect upon weight gain, compared to the untreated hives (blue columns); but that wasn’t the case in the Sunny Yard. Nor did there appear to be any consistent adverse effect upon colony strength in either yard. Take-home point: Never draw conclusions from the results of any experiment run only in a single yard!

And then my sons brought back a load of bees from the Pumpkin Patch …

Hives Returning from Pumpkin Pollination

In July Eric and Ian were scrambling to find 36 hives to move to a long-time pumpkin pollination contract. I told them that I was finished grafting for the year, and that there were roughly that many strong singles headed by 2nd-tier mite-resistant breeder queen colonies that I had no more use for, especially since some, in their second season, were allowing mites to climb a bit. So they put a half OA/gly sponge (25 g OA) in each one, slapped on a second deep of foundation and drove them to the farm.

This was an unusual site, since it is in an isolated irrigated desert valley in Nevada, and our hives were the only honey bees in the valley. The only forage was pumpkins, a little alfalfa, and some desert bloom. Most years, colonies do poorly there, and since we don’t bring the hives back ‘til late October (so that we can pick up pumpkins for Halloween), mite levels upon return are generally pretty high, and the colonies are in terrible shape.

But when the boys brought the hives back this year, they were all smiles, since the colonies were strong and plugged with honey. Out of curiosity, I performed mite washes on ten of them, to see how badly the mites had gone up. To our amazement, the mite wash counts were 0, 1, 0, 0, 0, 0, 1, 0, 0, and 0.

Practical application (perhaps a peek into the future of beekeeping?): Here were mite-resistant colonies that had received only a single mite treatment in two years — a single OA/gly sponge in their second summer. By early November (four months after application), the sponges contained little glycerin and were dry to the touch, and in many hives were largely chewed and removed (the remnants still tasted like straight oxalic acid). Yet these colonies kicked butt and came home heavy with honey and nearly free of mites. How cool would it be to be able to run all such mite-resistant colonies that require only one minimal treatment with OAE each year?

I know that this is going to sound like an institutional researcher making a pitch for funding, but we clearly need to perform more controlled trials to tease out whether OA/gly indeed suppresses colony buildup or performance, to what extent, from how long an exposure, the optimal time to apply it, and ultimately how it can best be used in an integrative pest management program to control varroa.

The Effect of Surface Area

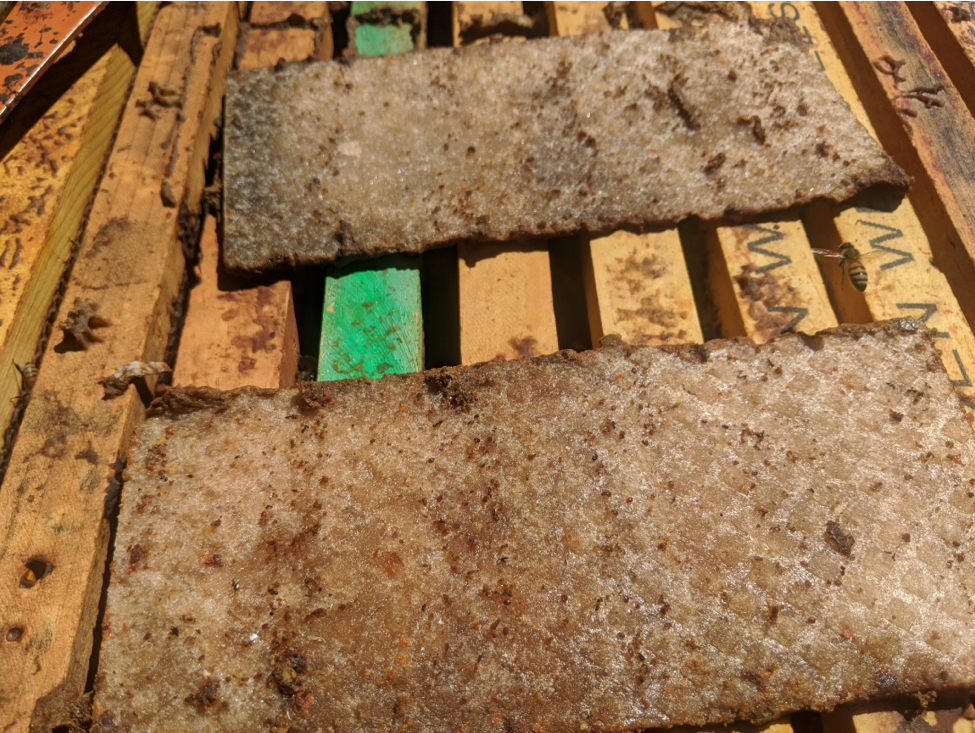

This year’s experiment with the Swedish sponges was instructive. They held a lot of OA/gly solution, and as the glycerin absorbed moisture, the sponges maintained a “wet” surface for a long time. They also had the advantage over shop towels that the bees didn’t chew them or even propolize them to any extent (Figure 5).

Fig. 5 Two OAE sponges after 42 days in a hive. My question then was, how much of the 50 g of OA was actually dispersed onto the bees?

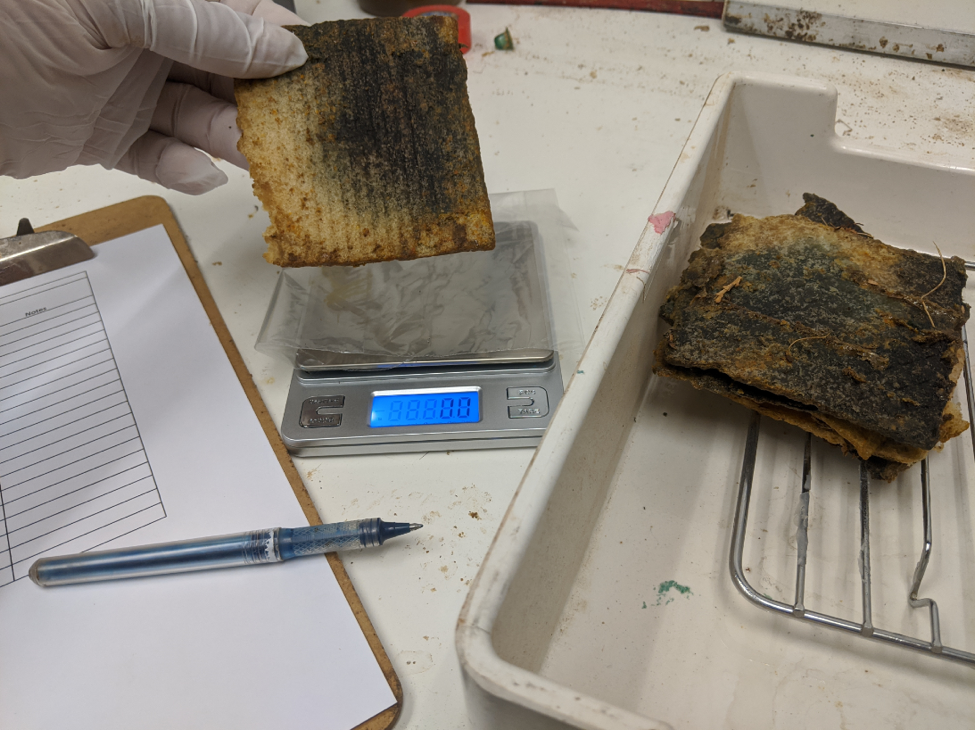

So I weighed some “spent” sponges (Figure 6).

Fig. 6 What I learned was that in California, where ambient relative humidity is lower than broodnest humidity, the glycerin in OAE sponges initially absorbs water once the sponges are placed in a hive, and the sponge initially increases in weight. But they then don’t lose much weight afterwards — the sponges still hold most of the original amount of OA even after two months in the hive.

When I air-dried fresh and “spent” sponges after removal from the hive, it indicated that of the 50 g of OA originally in two sponge strips, only 10-15 grams of OA was actually dispersed into the hive. And for the quarter strips that provided good mite control from June through the end of August, only about 4 g of OA were released.

Practical application: It doesn’t take much OA to control varroa in a hive if it is applied in the “right” way, and applied early in the season.

Possible Advantage to a Chewable Matrix

Although we liked the sponges for application of OAE, since the bees didn’t propolize them or inconsistently remove them too quickly, there may be an advantage to a matrix that the bees do chew away. In a previous experiment, we took stickyboard counts of mite drop following application of shop towels with different ratios of OA to glycerin. What my assistant, Brooke Molina, noted was that with some formulations, there was a pileup of towel residue on the stickyboard, just inside the hive entrance (Figure 7).

Fig. 7 Note the pile of shredded towel just inside the hive entrance. The towels had been placed on the top bars of the lower brood chamber of a double deep hive. The bees appear to have dragged the chewed-off pieces to the front of the hive, and then dropped them between the end bars and the inside hive wall.

Such movement of the OA-saturated towel material has the possibility of increasing distribution of the oxalic acid through the hive, but in a field trial we didn’t notice any correlation between the degree of chewing and efficacy of mite reduction.

OAE Compared to OAV

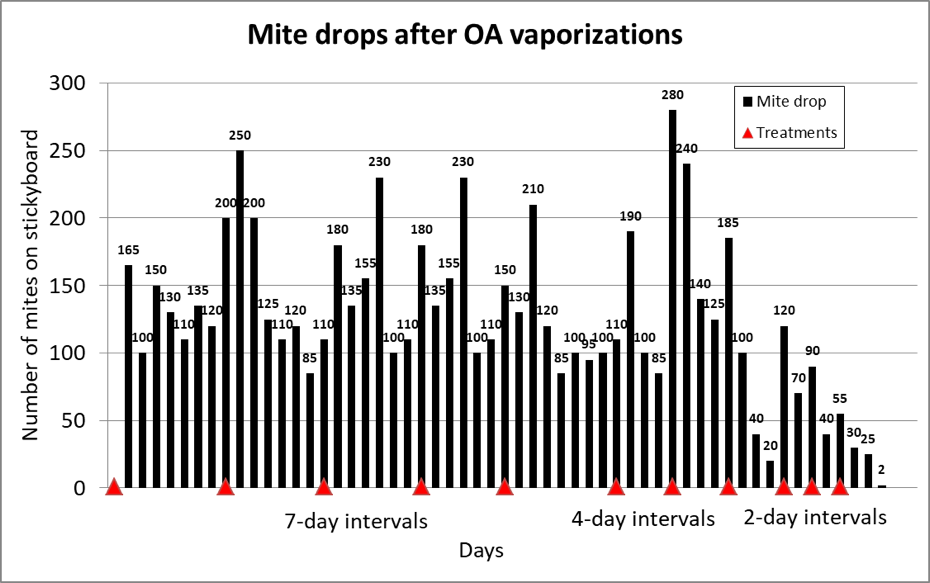

I recently received an interesting data set of mite drops following repeated oxalic vaporizations from beekeeper Edward Lutman of Port Orange, Florida. His data may help to explain why we need an extended-release application method for oxalic acid (Figure 8).

Fig. 8 Ed counted 7000 fallen mites over the course of 47 days (roughly three varroa reproductive cycles), starting after his first vaporization on August 18. He started with vaporizations (red triangles) at 7-day intervals, then shortened to 4 days apart, then to only 2 days.

Since each oxalic vapor treatment can kill over 90% of the mites on the adult bees [[5]], it’s pretty clear that when a colony is full of brood, one needs to keep hitting them with OA before they do a turnaround back into the brood. Ed got no apparent mite reduction with weekly vaporizations. It looks as though the 4-day intervals were finally working (although mite reproduction typically drops of its own late in the season). But it was the 2-day applications that finally brought the mite drop down to near zero.

Practical application: Although lots of beekeepers swear by OAV, it seems like a lot more work to me than simply inserting an OAE strip early in the season. OAE provides a continual dispersal of OA onto the bees.

OA/gly is a Long-Term Treatment

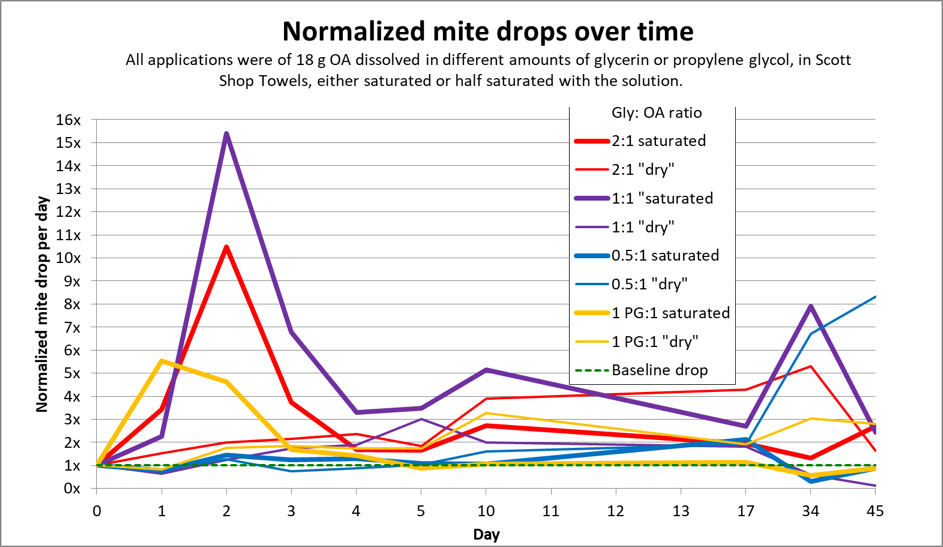

I showed previously [[6]] that the efficacy of OAE can increase with time (for up to 2½ months or more after application, dependent upon the matrix used). In 2018 I published the results of a field trial of application of various ratios of OA to glycerin (or propylene glycol) [[7]]. What I didn’t show were the results of a preliminary study that we had performed by applying each of the treatments to a single hive, and then tracking the mite drop and alcohol wash counts of those hives. Since there was only a single hive monitored for each treatment (n=1), it’s risky to draw any conclusions, but there were some obvious trends. The results may be meaningful as we attempt to determine the best way to apply the extended-release oxalic acid treatment. Let’s first take a look at the mite drop onto stickyboards following application of 18 g of OA on shop towels, with various amounts of glycerin or propylene glycol carrier, at two different saturation levels (Figure 9).

Fig. 9 For all OA:gly ratios, mite drops went way up (up to 15X) over the first few days, and then continued to stay above the baseline level (green dotted line) for some time. Note that the greatest increases in mite drop occurred in the hives given saturated (as opposed to half-saturated) towels.

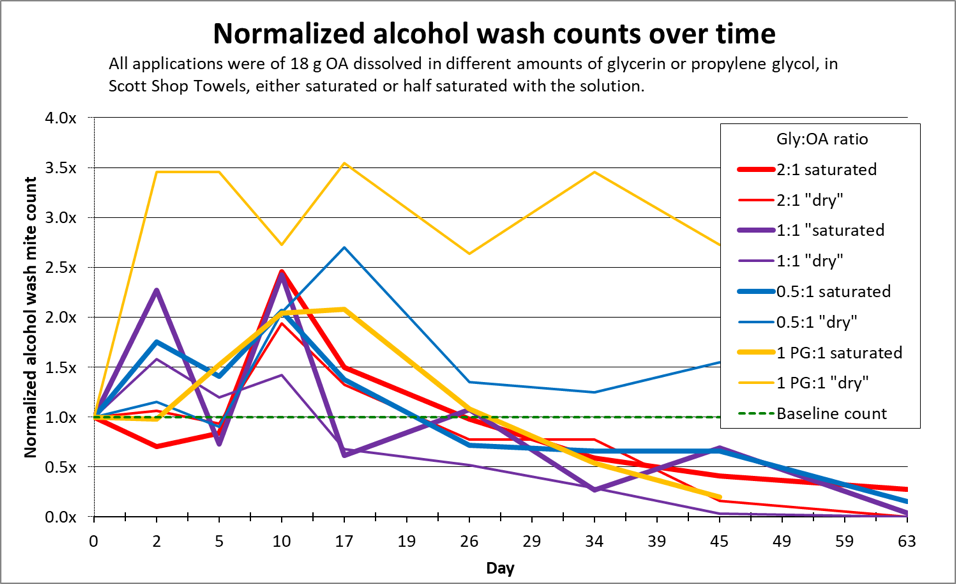

With so many mites dropping , it would be reasonable to assume that the infestation rate of mites on the worker bees would also quickly drop. But counterintuitively, that was not the case (Figure 10).

Fig. 10 Despite the high drop of mites from the bees, the infestation rate of the workers actually went up for nearly a month for most treatments (compared to the green baseline). What the heck?

This puzzling and unexpected phenomenon was consistent across the tested formulations, and thus has some very strong implications:

- Mite wash counts in the first month may underestimate the actual efficacy of OAE, and

- We need to figure out why the mite wash counts go up instead of down.

I racked my brain on this one, and could only come up with one explanatory hypothesis. And then on Zoom, I had the chance to ask a group of very smart beekeepers from Berkeley, California for their ideas for an explanation. After a few seconds, professional statistician Jim Veitch stated, “The treatment seems to be suppressing the mites from reentering brood cells.” Aha, I said — that’s exactly what I came up with.

Practical application: When OAE is applied on a matrix with lots of glycerin on the surface, it quickly gets dispersed onto the bees, and some of the “phoretic” mites quickly die. But they may be quickly replaced by emerging mites that do not drop off of the bees. Could it be that those mites, due to the treatment, do not reenter brood cells, and eventually die without reproducing? This brings me to Varroa Control Concept #1:

Varroa Control Concept #1: You don’t need to kill a single mite in order to completely control varroa. All that you (or the bees) need to do is to cut the mites’ rate of reproductive success in half, and they will slowly dwindle away.

And this may be exactly what OAE might be doing. If this is one of its modes of action, it would explain the above graphs, and why I’ve obtained much better efficacy in apiaries in which there is no outside mite immigration into the hives. It may also explain why some who have tested the method concluded that the efficacy was poor. My question then is, whether oxalic acid in glycerin is best used as a short-term treatment (with possible adverse effects upon the bees), or as a long-term treatment, applied when mite levels are still low.

Practical application: Extended-release OA/gly may be best used as a proactive treatment — before mite counts climb. It does not reduce the infestation rate in the short term as quickly as do formic acid, hops beta acids, oxalic dribble or vaporization, or thymol (I don’t have data for Apivar), but can surpass their efficacy in the long term. If approved by EPA, OAE may allow us to apply treatment when we put our honey supers on, and enjoy relatively mite-free colonies during the flow and into autumn. But it may not be able to deal with high rates of mite immigration.

Safety

Over the past several years, I’ve dribbled many thousands of hives with OA. And I’ve applied thousands of OA/gly towels and sponges. I’ve also used oxalic acid vaporizers on a number of hives.

The collective experience of me and my crew is that the application of OA by saturated pad or dribble is of low risk to the applicator — far safer than spraying, fogging, or vaporization. And application by pads made with the 1:1 ratio is the safest (and easiest) of all.

As far as mixing, over the past few years I’ve mixed over 300 lbs. of OA dihydrate with water, sugar syrup, glycerin and glycerin syrup, or other solvents, often with heating involved, and find that with reasonable care and a pair of safety glasses, it’s no more dangerous than handling any number of household cleaning products (such as lye, or oven or toilet bowl cleaners).

The heating of the 1:1 formula does increase the chance of accident slightly, but is not nearly as dangerous as cooking French fries. So long as one wears eye protection, hot OA/gly solution is not even as dangerous as spilling hot coffee on yourself (since coffee is generally heated to a higher temp). If the hot acid gets on your skin, it can be easily rinsed off with no harm — far safer than with formic acid, or hot fat from a French fryer. And OA residues are easily neutralized with a solution of baking soda (10 heaping tablespoons per gallon of water).

So far I prefer using the 1:1 w:w ratio of OA to glycerin, which does require heating. However, no heating is required at all for dissolving OA into glycerin at the 1:2 w:v concentration — it will dissolve completely at room temperature (it does take several hours. but requires minimal stirring).

So I’m hoping that EPA will approve the additional, and safer, application method for OA to the existing label.

Questions Still to Answer

Is there a better delivery matrix than the shop towels, cardboard, or sponges?

I’ve scoured the suppliers of absorbent materials, and have started testing them (Figure 11).

Fig. 11 A small test of five different matrices, weighed before and after a few weeks in a hive. I’m checking for OA weight loss, propolization, and chewing.

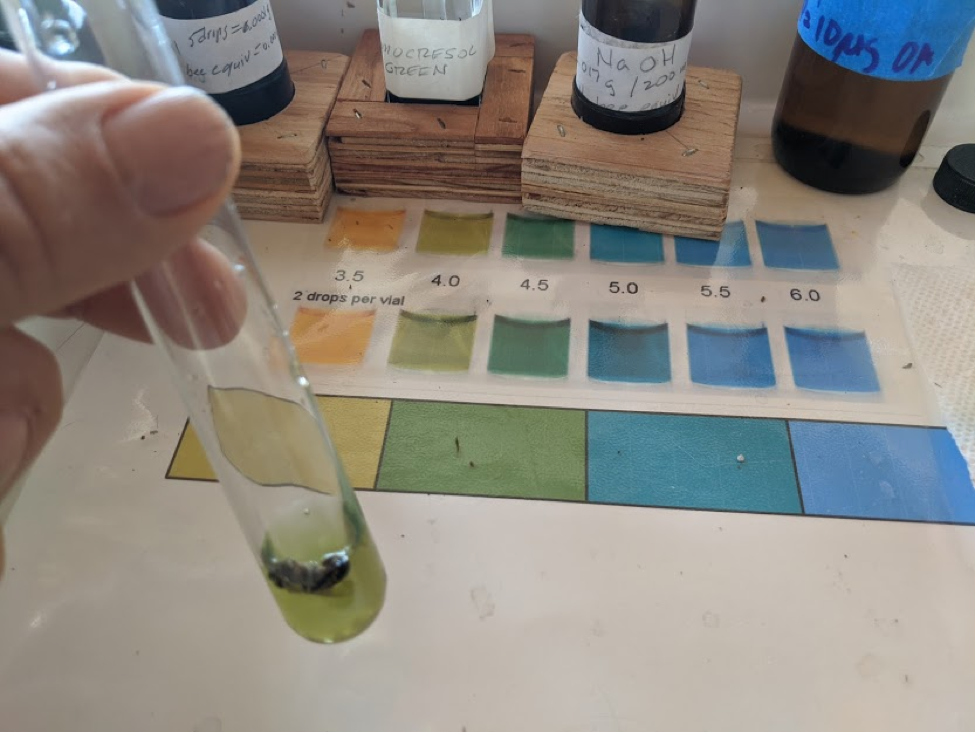

I now have on hand ten different cellulose or synthetic absorbent matrices that look promising. What’s likely the most important test will be to measure how much OA actually gets onto the bees’ bodies. I’ve developed a method to measure the oxalic residues on a bee, tested it in the field, and plan to use it next spring to track OA distribution in the hive after various application methods of OAE, comparing residue levels to those obtained by dribble and vaporization (Figure 12).

Fig. 12 By titration, I can quantify the amount of oxalic acid on a bee’s body down to micrograms. I’ve now got the method dialed in, and hope to learn a lot about oxalic distribution in the hive following various application methods.

What is the best time of year to apply OAE?

I’ve only tested it during the summer, and it appears to work best if applied while mite levels are still low. Application in June may control varroa until late summer or early fall. I haven’t tested it enough during winter to say anything, but have heard of yet-unpublished research that found that it worked well (and we’re testing winter application as I type these words).

Until then …

The Label is the Law

OK, OAE looks extremely promising. But this application method is not yet approved by the EPA. So unless you have a valid research authorization, it’s not yet legal to use for mite control.

Progress Toward Registration

As you may imagine, I continually get asked by beekeepers, “How soon will we be legally able to apply OA by the extended-release method?” This will require getting the EPA to modify the label for the registration of oxalic acid as a miticide. A petition has already been submitted to amend the USDA National Organic Program’s National List of Allowed and Prohibited Substances to include oxalic acid (including OAE) for varroa mite control [[8]].

There are actually three modifications to the “Application Directions” section of the label that would greatly benefit beekeepers:

- To add an additional application method (“Extended-Release Method”) that involves dissolving OA in glycerin, and then applying it in an absorptive matrix into the brood chamber.

- To allow the application of oxalic acid by solution, vaporization, or extended-release while honey to be harvested is on the hive.

- To allow the use of glycerin as the adjuvant for the “Solution Method” (the dribble, which currently specifies using sugar as the adjuvant).

The proposal for, and supportive data for, such modifications to the label must come from the Registrant of the product — the USDA. The USDA lab in charge of development of varroa control products is the Beltsville Lab, currently in transition as far as its Research Leader. I’ve been collaborating with Dr. Jay Evans in study design and by sharing my research findings on OAE. But since USDA is the Registrant, I’m not allowed to ask questions directly to EPA regarding the progress of modifying the label.

Q & A with Dr. Jay Evans

Dr. Evans is strongly committed to working toward getting this application method approved, and we have been in much discussion regarding ways to overcome the objections raised by some in the regulatory process. But since it’s not my place to speak for the USDA, I asked Dr. Evans to update us on the progress toward registration, as well as any hurdles involved. I presented him with a list of questions frequently asked of me by beekeepers, and asked him to answer them to the best of his knowledge.

Q: What are the steps involved in adding the proposed modifications to the label?

A: Thank you for the continued dialogue, Randy. As you know, we began these discussions in January 2017 and I respect your diligence as always. It has been a learning process for all of us and you have engaged the very top of the EPA decision tree as well as the USDA regulators who helped bring legal oxalic acid products to market in 2014. Everyone in this process is keen for safe, legal bee medicines, especially against varroa. I am a small bit in this, and will try to convey personal perspectives here. I do not claim to represent the entire regulatory chain. New or modified varroacide labels involve three branches of USDA, along with EPA, potential registrants and licensees, and of course stakeholders.

Q: What sorts of hurdles or concerns about registration are you experiencing?

A: On a practical side there have been concerns with identifying a consistently effective formulation and delivery vehicle. You and others have done extensive work to perfect the options but a simple, “universal” method is always better for assessing risk and efficacy. There are some concerns with at-home preparation of this (and any) deployed pesticide that do have to be addressed.

Q: What is the current status of ARS’s progress toward submitting the required paperwork to the EPA?

A: ARS scientists (primarily Dr. Steven Cook in our Lab) eagerly read data from quality OA-gly field trials from you, academic groups, and potential industry sponsors/licensees. We have submitted (favorable) data on residues following OA-gly treatments for an earlier version of the technique and will likely repeat these assays for the current, more effective delivery systems.

Q: Can you detail ARS’s specific plans moving forward toward getting this application method approved?

A: Bee advocates in the USDA Office of the Secretary, with USDA-ARS, USDA-APHIS, and EPA, are weighing all the options to move this and other varroacides forward. ARS is always willing to help gather evidence for efficacy and environmental risk for bee treatments and will continue in that role. As above, we have one scientist working almost exclusively on mite treatments and a number of others in our group pitching in. This is spread across OA-gly and other varroa treatments.

Q: A recent press release said: “Agricultural Research Service (ARS) entomologist Steven Cook will be leading a $1 million funded international consortium of scientists to seek new controls for Varroa mites, honey bees’ number one problem.” What portion of that $1 million is going towards OA/gly research?

A: Steve and a team from nine institutions (plus the Honey Bee Health Coalition) brainstormed for a year and targeted over ten candidates from industry and other sources. Two members of the team (Jennifer Berry at University of Georgia and Geoff Williams at Auburn University) used the funds devoted to their groups to partially offset the expenses of multiple OA-gly field trials in the southeastern U.S. Other group members are testing different candidates in the lab and field.

Q: How soon can we expect this application method to be legal for beekeepers to use? I realize that you can’t predict the future, but is there any expected time line?

A: I would be wrong to even guess.

Q: What can we beekeepers, either individually or through our associations, do to support and expedite the USDA’s registration of the extended-release application method? Would letters of support or petitions help?

A: Scientists and regulators appreciate polite, if frustrated, discourse, and do want to know what is driving and what is frustrating beekeepers. I don’t feel qualified to say whether this will move things differently or more swiftly in this case. There will be a group document in the next few months for would-be registrants, applied scientists such as yourself, and stakeholders to describe the most effective routes for proposing, sponsoring, registering and licensing new bee products. Elizabeth Hill in USDA is spearheading this and has great experience in bee science and regulation. This will be a first-ever roadmap given current bee-related regulatory policy and will be helpful for all of us.

Closing Thoughts

There are already companies in the process of registering OAE products. My fear is that if we don’t get it added to the label as a generic “approved application method” before EPA approves a commercial product, that we beekeepers will be stuck with only one or two commercial products to use, rather than being able to cheaply make our own (using, of course, a registered bulk oxalic acid). I hate for us beekeepers to succumb to the temptation of being pesticide scofflaws. If our industry steps up to the plate and communicates our concerns to the ARS and EPA, we may have a new way to control varroa legally, safely, inexpensively, and without contaminating our combs and honey.

Updates

I’ve had a lot of questions about extended-release oxalic acid (OAE). My covering of my experiments is informational only — this treatment is not yet approved in the U.S., and I am not in any way promoting its application. However, for those legitimate researchers with valid authorizations, below are some details of my materials and methods.

The Aluen CAP product uses a ratio of 1 g OA to 2 mL glycerin. This formula has the advantage that no heating is necessary to dissolve the OA (although it takes several hours to dissolve), and the OA stays in solution on the strips (it doesn’t recrystallize). The upside to this formulation is that it rapidly transfers OA onto the bees. The downsides are that such rapid transfer can result in worker agitation and brood kill, plus the strips are really sloppy to handle, and the acid solution tends to stick to everything you touch.

We have better success with a solution of 1 g OA to 1 g glycerin, heated to not above 170 F to dissolve the OA. The solution is supersaturated, and must be poured over the strips (on edge) to be absorbed before it cools. Overnight the OA will crystallize on the strips, creating a stiffer, “drier” strip that is far less messy, easier to handle, and does not cause too rapid a dispersal of OA into the hive.

Once in the hive, the glycerin in the 1:1 formulation absorbs moisture from the air, and “wets up,” slowly dispersing the OA onto the bees as they walk over the strips.

Swedish sponge cloths worked better than shop towels (but are pricey, and some brands fall apart with time; I’ll post results of other absorbent matrices in spring of 2021). “If you care” brand sponges from Amazon work well. Do not use a sponge that contains a moisturizer.

We mix 1000g OA with 1000 g glycerin in a stainless steel pan over a burner, stirring until it is clear, and watching the temperature carefully. Above 179F a chemical reaction takes place (I don’t know whether this is detrimental or not).

We cut the 7″ x 8″ sponges into halves or quarters. A full sponge absorbs 100 g of the hot mixture; the cut strips absorb proportionally.

We slowly pour the hot solution over the strips, then let them sit overnight to cool and crystallize. They retain their strength for at least 2 months.

Above we’re pouring a measured amount of hot solution over half sponges. They will need to be flipped once for even absorption.

Above is a shoe tub with a single layer of quarter sponges on edge. Making them like this requires no flipping if the solution is poured evenly over the tops of the strips.

I’m still working on optimal dosing of hives. A single 1-3/4″ x 8″ strp worked well for nucs and smaller colonies, especially when applied early in the season. A large colony may require 3-4 strips when laid across the top bars (the strips must be placed between the brood chambers, so that plenty of bees are walking over their top surface). Efficacy may be better if the strips are hung over the top bars, hanging between the frames, but this takes much more labor. Hung strips work well in nucs, singles, and for top-bar hives.

We use tongs to apply the strips. Use a solution of 10 heaping Tbl of baking soda in 1 gallon of water to neutralize hands and tools.

Citations

[1] Sabahi, Q, et al (2020) Evaluation of dry and wet formulations of oxalic acid, thymol, and oregano oil for varroa mite (Acari: Varroidae) control in honey bee (Hymenoptera: Apidae) colonies. Journal of Economic Entomology, XX(XX), 2020, 1–7 doi: 10.1093/jee/toaa218

[2] Higes, M, et al (1999) Negative long-term effects on bee colonies treated with oxalic acid against Varroa jacobsoni Oud. Apidologie 30(4): 289-292.

Hatjina, F & L Haristos (2005) Indirect effects of oxalic acid administered by trickling method on honey bee brood, Journal of Apicultural Research, 44(4): 172-174.

Martín Hernández, R, et al (2007) Short term negative effect of oxalic acid in Apis mellifera iberiensis. Spanish journal of Agricultural Research 4: 474-480.

Papežíková, I, et al (2017) Effect of oxalic acid on the mite Varroa destructor and its host the honey bee Apis mellifera, Journal of Apicultural Research 56(4) https://doi.org/10.1080/00218839.2017.1327937

Rademacher, E, et al (2017) Effects of oxalic acid on Apis mellifera (Hymenoptera: Apidae). Insects 8, 84; doi:10.3390/insects8030084

Terpin, B., et al (2019) A scientific note on the effect of oxalic acid on honey bee larvae. Apidologie 50, 363–368.

[3] https://scientificbeekeeping.com/extended-release-oxalic-acid-progress-report-2/

https://scientificbeekeeping.com/extended-release-oxalic-acid-progress-report-3/

[4] Maggi, M, et al (2015) A new formulation of oxalic acid for Varroa destructor control applied in Apis mellifera colonies in the presence of brood. Apidologie 47(4): 596–605.

[5] Al Toufailia, H, et al (2015) Towards integrated control of varroa: 2) comparing application methods and doses of oxalic acid on the mortality of phoretic Varroa destructor mites and their honey bee hosts. Journal of Apicultural Research 54(2): 108–120.

[6] Fig. 15 in Mite control while honey is on the hive, Part 2. ABJ 160(12); 1349-1356. Also the Pumpkin Patch hives.

[7] https://scientificbeekeeping.com/extended-release-oxalic-acid-progress-report-4/

[8] https://www.ams.usda.gov/sites/default/files/media/OxalicAcidTR.pdf