Thymol — a New Application Method? Part 1

Thymol products for varroa control 5

Reaction to the delivery matrix by the bees 6

Removal and dispersion of thymol matrices by the Bees 9

Thymol — a New Application Method?

Part 1

First published in ABJ in November 2022

Randy Oliver

ScientificBeekeeping.com

As our summers get hotter, some of the “natural” treatments against varroa have issues, since the adverse effects of both formic acid and thymol increase at high temperatures. Thus I’ve been experimenting with reducing and extending the release rate of oxalic acid and formic acid. But how about thymol — could we extend its release rate too? This summer I resumed some research that I’d initiated back in 2017.

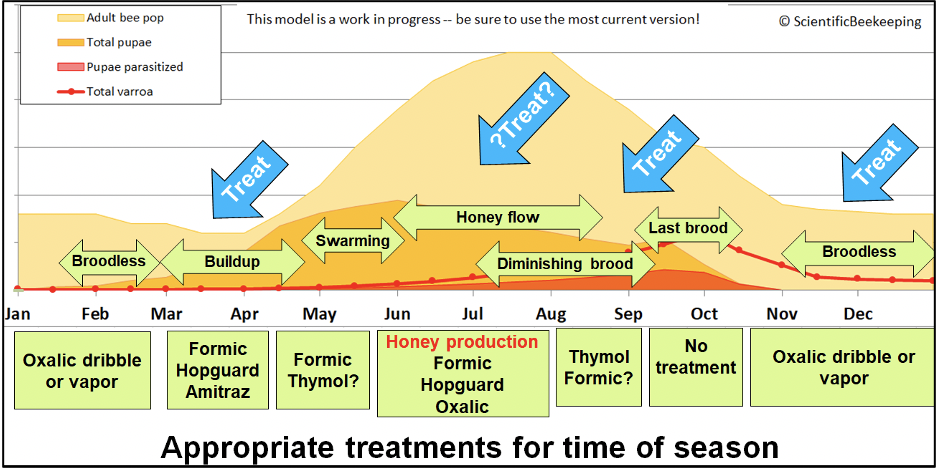

Thymol is a well-proven “natural” miticide, fairly well tolerated by the bees. My sons and I use thymol in rotation with oxalic acid and formic acid, with each miticide being appropriate for use during different “treatment windows” (Figure 1).

Fig. 1. I created the above generic chart (adjust the dates for your area) to point out the best treatment windows for varroa management, as well as the most appropriate active ingredients to apply during those windows. We’ve found that in the California climate, it typically requires at least four treatments per season to maintain low varroa levels (in non-resistant stock). To avoid the evolution of miticide-resistant varroa, we all must rotate different active ingredients.

Thymol, due to its temporary suppression of broodrearing, is appropriate for use if you can get harvestable honey off the hive before mid-August. It can also be used to both control mites and suppress colony buildup prior to swarm season.

In my state of California, there is only a single registered thymol product — Apiguard, with specific instructions as to how it can be applied. We’ve been happy with Apiguard, but that’s not to say that there might not be a more bee- and beekeeper-friendly way to apply this proven miticide. Some limitations of Apiguard are that:

- A space must be provided below the hive cover, which means that for those of us who use migratory covers, a spacer rim of some sort must be provided (Figure 2).

Fig. 2. The only thymol product approved for use in California is Apiguard “gel,” here applied in a spacer rim. My sons and I have successfully used it for many years in rotation with other treatments, mainly during hot weather in August, when we don’t mind its temporary suppression of broodrearing during our dearth period.

- For full efficacy, the treatment must be repeated, which takes extra labor. We’d much prefer a treatment that requires only a single application.

- The label no longer allows for placing the product between the brood chambers, which would be important for application during cool weather.

- Application above the brood chamber is only efficacious if the colony is strong enough to remove the treatment from the card above the top bars (my own observation). A treatment that could be applied between the brood chambers would be of great benefit.

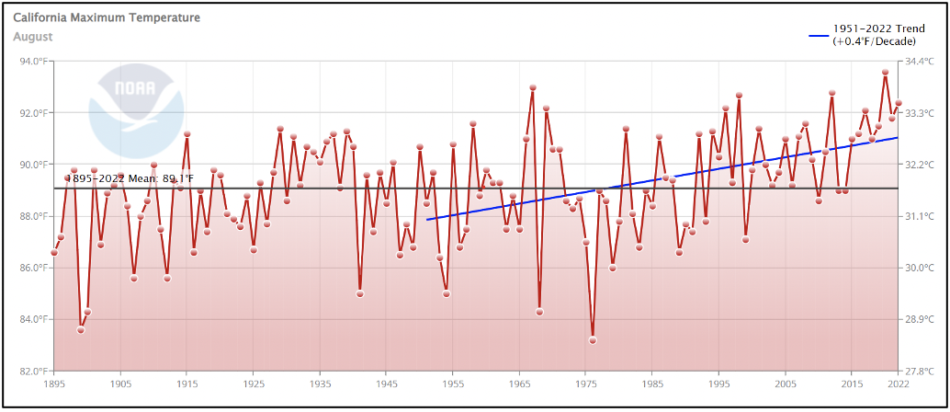

- Although Apiguard can be applied at daily highs of up to 105°F, our summers are getting warmer (Figure 3), and during our optimal treatment window in August this year, it got even hotter than that.

Fig. 3. The blue trendline reflects the increase in California’s average August high temperature over my lifetime. It’s not just that I’m getting older — it really is getting hotter! You can plot similar charts for your area at https://www.ncei.noaa.gov/access/monitoring/climate-at-a-glance/statewide/time-series.

- Perhaps most importantly, when we apply Apiguard as per the label, the broodnest is greatly impacted — the vapor kills the eggs and young larvae directly below the treatment (which the nurses then cannibalize), and then the colony reestablishes a divided and reduced broodnest to either side of the treatment.

Practical application: Apiguard is a great product, but I suspect that there could be even better application methods appropriate for our conditions and colony management. But we beekeepers are legally precluded from tweaking the application methods specified on the label, or from using generic thymol to apply by different methods.

“Off-Label” use of thymol

Practical application: Varroa treatments are registered as pesticides. When a manufacturer goes through the tortuous and expensive process of registering a pesticide, they must provide a specific set of approved application instructions. Any deviation from those instructions is a violation of the law.

The situation is more reasonable with medicines: “From the FDA perspective, once the FDA approves a drug, healthcare providers generally may prescribe the drug for an unapproved use when they judge that it is medically appropriate for their patient” [[1]]. This is referred to as “off label” use, and is very common in medicine.

Doctors and their patients are allowed to experiment and learn about how best to use medicinal drugs under different circumstances, and for not-yet-registered uses. Unfortunately, this freedom does not apply to registered miticides, so we beekeepers (or even our veterinarians) are not allowed to tweak application methods to account for the wide range of situations that we encounter in beekeeping.

EPA’s refusal to consider granting us beekeepers an Own Use Exemption for the organic acids and thymol frustrates me, since it prevents us from learning how to apply these safe and inexpensive generic substances to our colonies, instead forcing us to purchase and follow the rigid label instructions for expensive registered formulated products.

Here’s the rub: As explained by USDA [[2]]: “Relative to miticide uses on agricultural crops, applications of varroacides to bee colonies are considered a minor use that may not allow for registrants to justify the costs to develop varroacides and break-even on such investments, given the small relative market potential.” So we can’t expect manufacturers to bring a bunch of customized varroa control products to market.

A plea to our national organizations: Registrants are reluctant to go through the tedious process of updating their labels, so we beekeepers are stuck between a rock and a hard place. As far as EPA’s mandate to avoid unreasonable risk to man or the environment, beekeeper use of generic off-the-shelf formic, oxalic, or thymol would pose no such risks. The government of New Zealand wisely recognized this, and gave beekeepers an exemption to use these “natural” products for varroa control however they wish. I suggest that our national organizations approach our senators and congressional representatives to legislate an Own Use Exemption similar to New Zealand’s.

The reality is that due to our limited arsenal of approved formulated varroa-control products, many beekeepers have unfortunately become “pesticide scofflaws.” I gotta walk a fine line with my research, which I do for the benefit of all, rather than for profit. I obtain Pesticide Research Authorizations from my State’s department of pesticide regulation, and publish my findings as scientific research only — I am not in any way suggesting that beekeepers use any unregistered product, or not follow label instructions exactly (I gotta cover my donkey).

Thymol products for varroa control

There are three main thymol products registered in North America for varroa control — Apiguard, ApiLife Var, and Thymovar. Only two are registered in the U.S., and only Apiguard in California. All work by the evaporation of thymol vapors from an inert matrix, and call for placing the treatment a few inches from the brood. Thymol is generally recommended for application during moderate ambient temperatures — typically between 20-25°C (~68-77°F), although some product labels allow application at higher temperatures. All specify not to apply while honey for harvest is being produced.

One widely-used product is ApiLife Var, which is a mixture of thymol, eucalyptol, menthol, and camphor, impregnated into a vermiculite wafer. I tried ApiLife when it was first released in the U.S. (read my report at [[3]]), and found that it was more irritating to the bees than straight thymol, likely due to the additional essential oils. But it may be this additional irritation to the bees — and mites — that gives it greater efficacy at low temperatures, or promotes its distribution throughout the cluster.

Thymovar, also registered in a number of countries, is a cellulose sponge strip impregnated with straight thymol crystals.

Apiguard uses a gel-like matrix of water and polyacrylate (such as is used in diapers) to suspend fine crystals of thymol, which slows the evaporation rate. In my experience, its efficacy is dependent upon the bees physically carrying away the particles, rather than simple evaporation.

I’m also aware that a number of beekeepers mix up their own “homebrew” thymol formulations, sometimes with the addition of other essential oils. I’ve tested some of these homebrews (which can be efficacious), but am most interested in straight thymol.

Understanding Thymol

Thymol appears to affect the mites by exposure to its vapor. It not only causes direct toxicity, but may also irritate them, or perhaps affect their critical sense of smell. In addition, thymol vapors can cause bees to engage in more intense cleaning behavior, or even brood removal. But it’s clear that thymol has a far greater adverse effect upon varroa than it does upon the bees (especially adult workers, who “get used to it”).

Contrary to popular belief, thymol is not highly volatile — if you put a few thymol crystals out in a tray to evaporate, it takes many days for them to do so, even at broodnest temperature. It’s really difficult to find data on thymol’s vapor pressure, but it appears to be far less volatile than water, kerosene, or perhaps even vegetable oil. If I stick my nose into the mouth of a jar of thymol crystals I can smell a faint odor; if I do the same with a jar of menthol crystals, the odor is intense, and my eyes and lungs burn.

The slow evaporation of thymol is affected by temperature, as well as the crystals’ exposure to air flow (which can be notably increased by the fanning of the bees). With Apiguard, the thymol is ground into fine crystals, which are suspended in a mixture of water and absorbent globules of sodium polyacrylate — very little thymol actually dissolves into water. Thus, the bees must actually remove the globules of gel to expose the surfaces of the crystals to evaporation.

With Thymovar, the crystals are more exposed, and can evaporate more quickly (sometimes causing excessive brood issues in hot weather).

Practical application: I wondered whether there was another way to apply thymol, that extended its release rate to avoid the need to reapply the treatment, that did not encourage propolization, that did not require the addition of a rim, and possibly be a matrix that the bees would remove themselves after treatment (such as happened when I applied a low dose of Apiguard between the brood chambers on an index card [[4]]). Ideally, a perfect treatment would not be excessively irritating to the bees, and would not shut down broodrearing for an extended period.

Reaction to the delivery matrix by the bees

Bees are repelled by a strong odor of thymol, and will attempt to enclose it in a curtain of propolis. But once its outgassing slows, the workers acting as “housecleaner/janitors” will either encase it in propolis (Figure 4), or pick off pieces of the matrix and remove it from the hive (Figure 6).

Fig. 4. If the cleaner bees are unable to chew away a matrix that smells of thymol, they will either build a wall of propolis around it, or encase it in a layer of propolis as above.

Thymol in Shop Towels

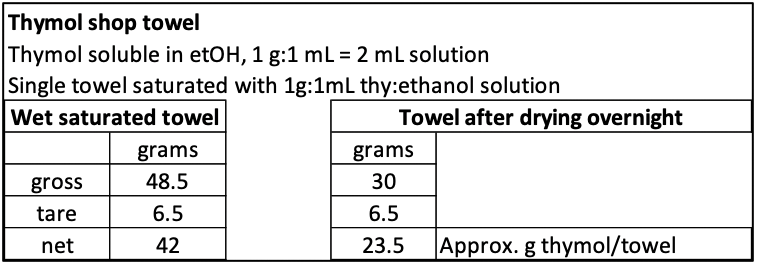

One of the delivery matrices for thymol that I tried was the commercial beekeepers’ standby — the blue shop towel. I found that a saturated solution of thymol could be easily made by dissolving it in denatured alcohol (especially if the alcohol was warmed) (Figure 5).

Fig. 5. A gram of thymol readily dissolves into a milliliter of denatured alcohol, resulting in ~2 mL of a saturated solution. The solution wicks readily into a shop towel. I then just laid the towels out to dry for an hour, by which time (at least in our California dry air) the alcohol had all evaporated. Due to the low vapor pressure of the thymol, there is nearly no weight loss of thymol. I then placed the dried towels into an airtight container for storage.

I applied the towels to test for removal and adverse effects. I placed half towels (containing a typical dose of ~12 g of thymol), in hot weather, either between the brood chambers, or in rims below the hive cover (Figure 6). It was quickly apparent that 12 grams on a towel in the middle of the cluster was too much, as the colonies roared and bearded out the entrances (I was afraid that they might abscond). That intense a dose also resulted in some removal of sealed brood. A quarter towel (containing ~6 g of thymol) was better tolerated.

Fig. 6. Half a thymol-impregnated shop towel in a rim. At first the bees are repelled by the fumes and fan them away. But as soon as the intensity of vapors drops, they rapidly remove every trace of the towel, rarely propolizing it.

What was interesting to me was the surprisingly rapid rate that the bees evaporated the thymol from the towels placed in the middle of the cluster. Unlike with Apiguard or Thymovar, it was like a “flash” treatment, and after a couple of days I could barely smell thymol in the remaining towels. Apparently, the temperature of the broodnest, coupled with the strong fanning, results in rapid thymol evaporation from this thin matrix, and janitor bees then quickly remove the remaining mildly scented towels.

A friend tried the towels in a few colonies, taking before and after mite counts. The results were that a half towel placed in the middle of the cluster resulted in substantial mite reduction, but was very stressful to the colony. A quarter towel was much better tolerated, but required a repeat application for efficacy. The towels placed in a rim above the hive gave variable results.

Practical application: The take home is that a shop towel, due to its high ratio of surface area relative to volume, allows for too-rapid release of the thymol for most purposes (but might be used in broodless colonies [[5]]). This thus raises the question of whether a cellulose matrix thicker than the Thymovar sponge would allow for a more controlled and extended release of thymol vapors as the thymol vapor from the interior of the matrix slowly diffused to the surface.

Removal and dispersion of thymol matrices by the Bees

Practical application: I’ve found that when Apiguard is placed above the colony, unless the bees physically remove Apiguard from the card it exhibits low efficacy against varroa. I suspect that the process of physical transport through the cluster is important, since it would expose the surfaces of the chewed particles of the matrix to allow for evaporation of the thymol. So an important question is, do the cleaner bees drag the particles down through the brood area (thus exposing the mites there to the fumes), or do they avoid that area?

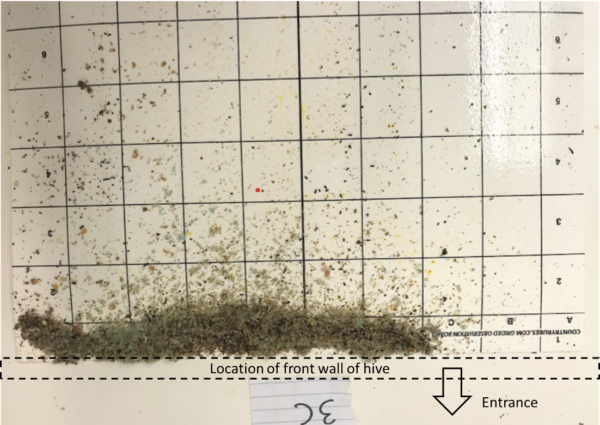

We made an interesting observation some years ago when we had stickyboards under colonies treated with shop towels infused with oxalic acid and glycerin (Figure 7).

Fig. 7. When the housecleaner bees chewed away shop towels infused with oxalic acid and glycerin, the particles of debris nearly all wound up piled on the stickyboards, heaped just inside the entrance, suggesting that the janitor bees took routes that avoided the broodnest.

Curious, we recently set up a hive to determine whether the cleaner bees do the same with debris containing thymol. We put a stickyboard under a colony, and applied two different thymol treatments on the top bars between the brood chambers — one a half shop towel impregnated with thymol, the other scoops of Apiguard (mixed with a fluorescent tracer). We placed each treatment separately on different sides of the hive. I wanted to see whether the bees would again carry the debris to the front of the hive, or whether it would be taken (or fall) down through the broodnest (Figure 8).

Fig. 8. We placed fluorescent-tagged Apiguard on the top bars of one side of the broodnest (the far side in this photo), and a half thymol-infused shop towel on the near side. This image (under UV + natural lighting) was taken four days later, confirming that plenty of particles of each matrix somehow sifted their way directly down through the broodnest, rather than being carried out away from the brood (the gray-bluish debris in the foreground is from the shop towel). This dispersion of the matrix through the broodnest likely increases the exposure to the mites to the thymol vapors, since the thymol would evaporate rapidly from the surfaces of the small particles of debris as they were carried (or sifted their way) down.

Extended-Release Thymol?

Note that all the registered thymol products call for repeated applications to achieve good efficacy. If we could come up with a treatment that extended the release of thymol even longer than does Apiguard, we might be able to get by with only a single application.

This got me wondering whether we could use a thicker cellulose matrix than used by Thymovar, to throttle the evaporation rate over a longer period of time, allowing us to get by with a single application. And would a matrix that encouraged physical transport by the janitor bees increase efficacy?

A Thicker Matrix

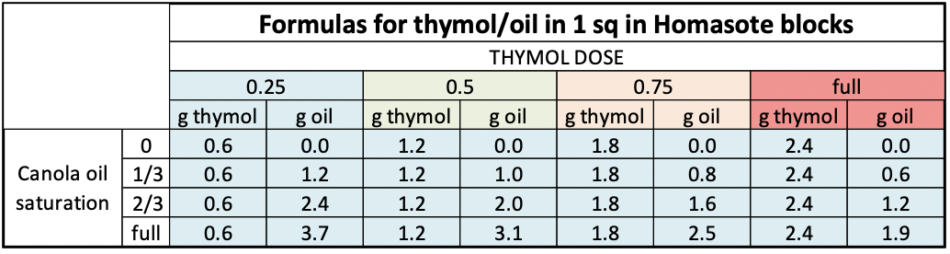

I was intrigued by the Homasote insulation board (made from recycled newspaper) used by NOD to make its MiteAway II pads. So back in 2017, assisted by Tara McKinnon, we experimented with it. Other beekeepers were dissolving thymol in vegetable oil or Crisco for their homebrews, so I wondered whether the thymol would work better if canola oil was added to slow evaporation, or possibly help it to stick to the bees’ bodies. So we made up a 4-way grid of sixteen different thymol and canola oil concentrations (Figure 9), dissolved them in ethanol, and saturated 1” square blocks of Homasote with them (Figure 10).

Fig. 9. We tried sixteen different ratios of thymol and canola oil. The amount of each substance that would remain in each 1” square block of Homasote is shown above. Those amounts ranged from 0.6-2.4 g of thymol, and zero to 1.9 g of oil.

Fig. 10. Preparing the test blocks. These have just absorbed the solutions.

We then placed sets of 16 test blocks into four hives between the brood chambers (Figure 11). This allowed us to test for how the bees responded to the intensity of thymol, as well as to the addition of oil.

Fig. 11. Note the range of oil saturation, as indicated by the darker color of the blocks containing more oil. There were thymol crystals on the surfaces of all the blocks other than the most oil-saturated.

Tara then opened the hives daily, and recorded how the bees were responding to the blocks, as far as avoidance, chewing, or propolization (Figure 12).

Fig. 12. There was of course colony-to-colony variation, but we learned that the bees tended to propolize blocks containing more oil, whereas after a few days they started chewing away blocks with less oil.

This finding suggested that blocks of Homasote containing thymol alone (no oil), might work well as an extended-release cousin of the Thymovar strips.

moving ahead to 2022

I shelved the above thought until this year. Since I’ve recently been experimenting with extended-release formic and oxalic acids, I figured that I should pick back up on my experimentation with thymol and Homasote. But I’m out of space, so you’re going to have to wait until next month to see what we learned.

Citations and notes

[1] Understanding Unapproved Use of Approved Drugs “Off Label” | FDA

[2] Varroacide Registration : USDA ARS

[3] IPM 7 Fighting Varroa The Arsenal: “Natural” Treatments – Part 2 – Scientific Beekeeping The application instructions on the label are surprisingly confusing, but Veto Pharma has some useful videos on its website.

[4] The Learning Curve – Part 3: The Natural Miticides – Scientific Beekeeping

[5] Chiesa, F & M D’agaro (1991) Effective control of varroatosis using powdered thymol. Apidologie 22(2): 135-145.